Regenerative Cycle – Definition, Advantages and Methods:

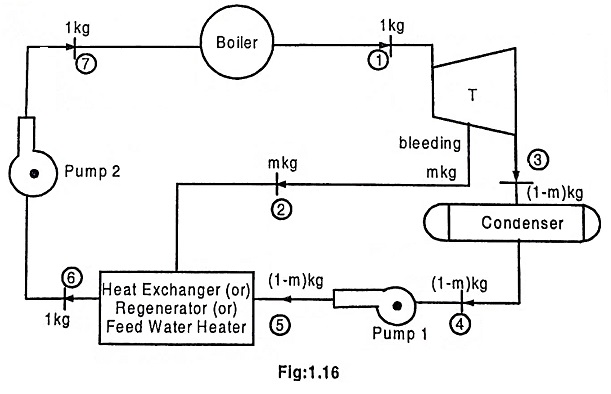

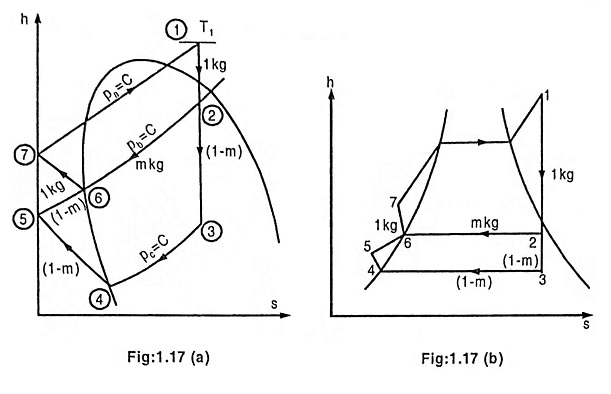

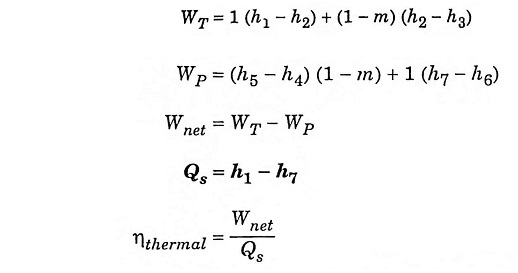

Regenerative Cycle – Assume 1 kg of steam is expanded in the turbine. Before complete amount of steam is expanded, some amount of steam (m kg) is extracted (this process is called bleeding) and utilized for heating the feedwater. So remaining amount of steam (1 – m) kg is completely expanded in the turbine and condensing in condenser.

In the regenerator, m kg of high temperature steam and (1 – m) kg of condensate are passing. Heat transfer from steam to condensate (feed water) takes place. So this process increases the enthalpy of feed water. Thus the heat supplied to boiler will be reduced.

Re-generation means heating the feed water by steam taken from the turbine. The steam is exhausted (or) bled from the turbine at several locations (before exhaust) and is supplied to regenerator (feed water heater) to heat the feed water. Extracting the steam in the turbine before exhaust is called bleeding.

Energy – balance

Assume 1 kg of working fluid is circulated.

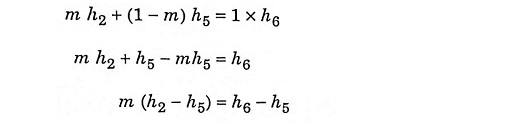

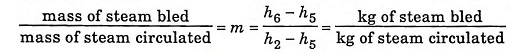

Energy entering regenerator = Energy leaving regenerator.

Take h1, h2, h3 from mollier diagram (h – s diagram) (or) from steam table.

h4 = hf for condenser pressure p3 = p4

h6 = hf for regenerator pressure p6 = p2 = p5

h5 – h4 = vf(p6 – p4) x 102 [p is in bar; p x 102 = kPa]

[vf for condenser pressure Pc = P3 = P4]

h7 – h6 = vf(pa – pb) x 102 [pb for regenerator pressure and vf for pb]

Advantages of Regenerative cycle:

- Heat supplied to boiler becomes reduced.

- The heating process in the boiler approaches the reversible process.

- Since feed water temperature is high, the range of temperature in the boiler is minimum. It reduces the thermal stresses produced in the boiler.

- Thermal efficiency is increased since the average temperature of heat addition to the cycle is increased.

- Due to bleeding in the turbine, erosion of turbine due to moisture is reduced.

- Condenser can be a smaller size.

This type of heating arrangement gives the efficiency equivalent to the Carnot cycle efficiency. This type of arrangement cannot be used in practice because steam becomes too wet in the later stages of the turbine. In actual practice, the advantage of regenerative heating principle is taken by bleeding a part of steam from the turbine at certain stages of expansion and it is used for heating the feed water in the separate feed heaters. This arrangement does not reduce the dryness fraction of remaining steam passing through the turbine.

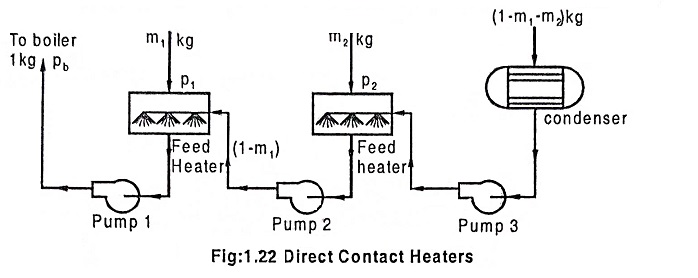

There are different methods of using the bled steam for heating the feed water as discussed here.

Methods:

(a) Direct contact heaters:

The steam bleed from the different points of turbine is mixed directly with the feed water to increase the temperature of feed water and the steam mixed with feed water is extracted with the help of the pump and supplied to the boiler.

The main disadvantage is that

The pump has to work with hot feed water. So this system is normally not used in practice.

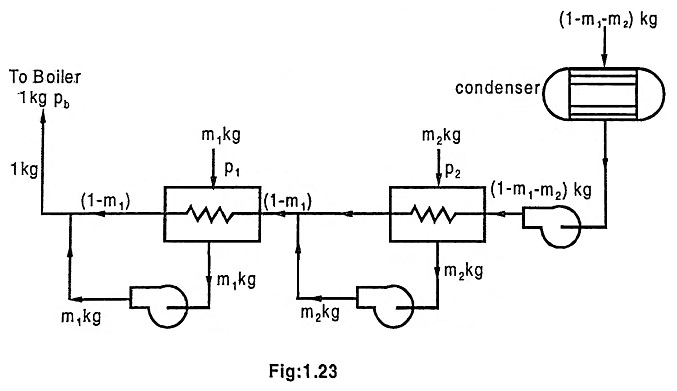

(b) Drain pump method:

In this method, the feed water is heated with indirect contact of bled steam in the heat exchangers. The bled condensate is extracted by the drain pump discharges into the feed pipe line. This method also suffers from the same disadvantage as mentioned in the direct contact heaters arrangement.

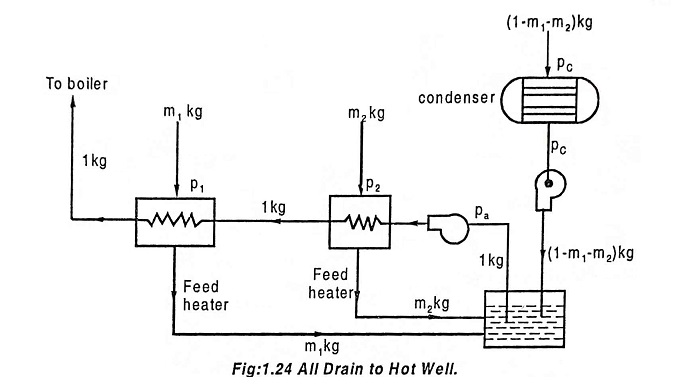

(c) All drains to hot well:

All drains to hot well method is shown in Fig.1.24.

In this method, the condensate of bled steam coming out from the indirect heat exchangers is fed to the hotwell. The total condensate (Condensate coming from condenser + Condensate from bled steam) from the hot well is pumped to the boiler through the regenerative feed heaters.

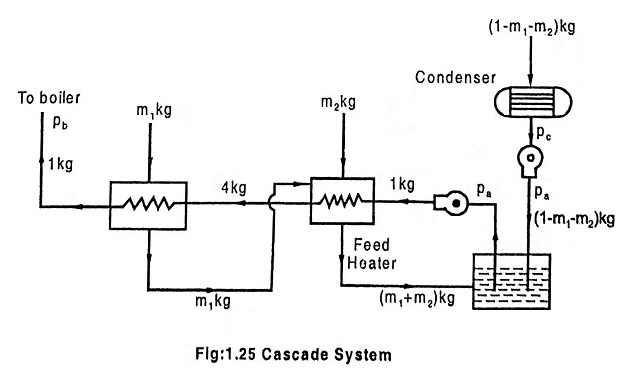

(c) Cascade System:

In this method, the condensate of bled steam coming out from the first heat exchanger is passed through the second heat exchanger and lastly to hot well as shown in Fig.1.25.