Drive Considerations for Textile Industry:

There are several processes involved by the dine the finished cloth comes out of a mill from its basic raw material, cotton picked up from the fields. The requirements of the motors are different for different processes. These mainly depend on the nature of the process. The several stages in the Textile Industry and the requirements of a drive motor for each stage are discussed in the following:

Ginning: The process of separating seeds from the raw cotton picked from the field is called ginning. This may be done in the mills located near the fields or in the industrial location itself. In the former the ginned cotton is transported to the industrial area in the form of hales. The ginning motors must have speed ranges of 250 to 1450 rpm. The load speeds are fairly constant. No speed control is required.

Commercially available squirrel cage induction motors may be employed.

Blowing: The ginned cotton in the form of bales is opened up and is cleaned up very well. Normally three phase Induction Motor may be used for the purpose. No speed control is required. The motors having synchronous speed of 1000 or 1500 rpm may be employed.

Cording: The process of converting cleaned cotton into laps is done by lap machines which are normal three-phase standard squirrel cage motors. These laps are converted to slivers by a process called cording. A motor used for cording is required to accelerate a drum having a large moment of inertia. It is required to withstand prolonged accelerating periods. To meet these requirements the motor selection must be made. The motor selected must have a very high starting torque and low starting current so that starting losses are kept to a minimum. The motor must have sufficient thermal capacity to withstand the heat produced by the losses occurring during prolonged acceleration. These cord motors are standardised in IS:2972 (part II) 1964 which gives the specifications for cord motors.

Normally, three-phase totally enclosed or totally enclosed fan cooled squirrel cage induction motors with high starting torque may be employed. The rating of the motor depends upon the type of fabric. Smaller rating motors in the range 1.1 to 1.5 kW may be used for light fabric. For heavy fabric the rating increases to 2.2 to 5.5 kW. The operating speeds of these motors are in the range 750-1000 rpm. Squirrel cage motors (8/6 poles) having synchronous speeds in the range of 750-1000 rpm are normally employed. The motors may be started directly from the line to achieve good starting torque. Slip ring motors may be advantageously used with rotor resistance starters as they give high starting torque at low starting currents. Once started the operation is continuous and uninterrupted.

These slivers are converted to uniform straight fibre by means of drawing machines. These are also normal standard motors. However, the motor selected must be capable of stopping instantaneously, in case of sliver breaking. The drawing machines are sometimes self brake motors which satisfy this requirement. The motor is subjected to inching to place up the broken sliver again. The inching operations may amount to 20. When the brake forms an integral part of the motor there is no necessity for a clutch and the motor becomes compact.

Combing and lap operations take place after slivers are straightened in a drawing machine. The motors used for these operations are also normal squirrel cage motors. The combing process upgrades the fibre. The slivers are converted into laps before combing.

The next process is spinning. Before the thread is ready for final spinning it is thinned down in two or three stages by processing it on a fly or speed frame. A motor with smooth acceleration is necessary to rive Considerations for Textile Industry in this frame. The drive motor should be capable of working in high ambient temperatures. The motor must be totally enclosed, with a clean floor construction. This is to prevent the cotton fluff from getting deposited on the motor surface, which may lead to poor cooling of the motor as well as burning of fluff due to motor heating. The motor must have uniform acceleration having thermal reserve.

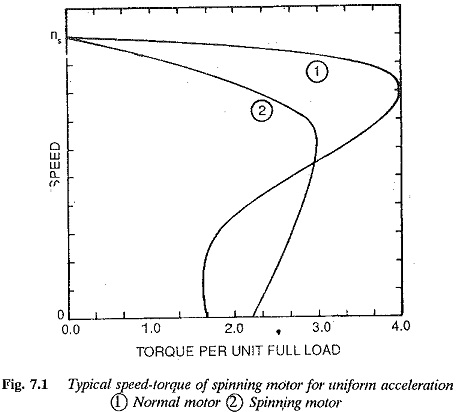

During spinning process the yarn is twisted and made to have sufficient strength. These spinning motors are standardised in IS:2972 (part III) 1965, which gives the specifications for spinning motors. The strengthened yarn is wound on bobbins. The spinning motor must be capable of drawing, twisting and winding operations. The breakage must be minimum and the yarn produced must have uniform tension. These motors also must have uniform acceleration to avoid yarn breakage. For a motor to have uniform acceleration, its speed-torque characteristic must be as shown in Fig. 7.1.

Its starting torque must be 150-200% and the peak torque 200-250%. The difference between these torques must be constant as the motor speeds up and must be small to ensure uniform acceleration. The acceleration is also slow and smooth. This is to avoid yarn breakage. A normal motor is, therefore, not suitable for this process. The motor must have an acceleration time of 5 to 10 s. The operating speed is 500 rpm. The kW rating of the motor is decided by ring frame; number of spindles, ring diameter and spindle speed. When once the initial build is over the motor may run at a higher speed. A two speed pole change motor may be used. It must have constant torque operation at both the speeds so that uniform tension is assured both at starting and running. One can employ two different motors, one for starting and low speeds and the other for high speeds. In either case the motors are costly. Two speed pole change motors are bulky and costly. However, the increased uninterrupted production may compensate for the cost. A two motor drive is also costly but has several advantages. It allows setting of any speed difference by adjusting the pulley diameters and speed ratios. The yarn tension can be adjusted independently. There is no interruption in production even when one motor fails.

For mule spinning, a group drive may be employed. The motor employed should have high starting torque as well as high operating slip. A slip ring motor with rotor resistance control or high torque cage motors may be employed for the purpose. When an individual drive is used, the motor chosen should be able to take care of peak power demands and must have higher slip.

For operthions like winding, warping and sizing, normal motors may be employed. Low speed motors are required. Reduction in speed using a gearing unit may be accomplished. When the yarn is transferred from the bobbin, a speed drop of nearly 100 rpm is required. So for these operations high slip motors are preferred.

Looms: The weaving of yarn into cloth is done in looms. The drives may be either semi group drives or individual drives depending upon the quality of the cloth required. The speed of operation is normally 600 to 750 rpm. Requirements of a loom motor are:

- Starting torque must be’high to complete the pick up job in a very short

- The duty cycle consists of frequent starting and stopping. The load on the loom motor is variable and intermittant. To avoid frequent starting and stopping the motor may be decoupled (or coupled) from the load by means of a clutch.

- The operation requires a reciprocating mechanism. Actually rotary motion must be converted to linear reciprocating motion. The current and torque pulsations are present. A flywheel is required for smoothing.

- These are also located in places where dust accumulates on the motor. The cotton fluff should not get collected on the motor surface to avoid burning of the same due to motor heating.

- Loom motors must withstand the effects of humidity.

To suit to the above requirements the loom motors are normally totally enclosed three-phase induction motors with high starting torque. Fan cooling of the motors is also employed. The fan cooling helps to avoid the collection of cotton fluff on the motor surface. The motor must be designed, taking into consideration the possible torque and current pulsations due to reciprocating motion. The surface of the motor must be such that it does not collect any cotton fluff. The kW rating of the motor selected must be decided taking into account the frequent starting and stopping in the duty cycle. The size of the loom motor depends upon the fabric. For light fabric, motors of rating up to 1.5 kW and for heavy fabrics motors of rating. 2.2 to 3.7 kW are employed. Speeds of motors are in the range of 100 to 750 rpm. Brake motors may be used here so that motor stops automatically in case the thread breaks.