IC Fabrication Articles:

Processing of Semiconductor Materials: Preparation of Silicon and Germanium – Silicon is one of the commonest elements on earth. It occurs as silicon dioxide (SiO2) and as silicates; mixtures of silicon and other materials. Germanium is derived from zinc or copper … (Read More)

Diode Fabrication Process and Packaging: Alloy and Diffused Diodes – Two commonly used techniques for Diode Fabrication Process and Packaging are the alloy method and the diffusion method. To construct an alloy diode, a pn-junction is formed by melting a tiny … (Read More)

Transistor Construction Techniques and Performance: The following are Transistor Construction Techniques and Performance are as follows, Current Gain: Good current gain requires that most charge carriers from the emitter pass rapidly to the collector. So, there should be little outflow of charge carriers … (Read More)

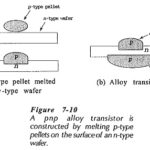

Transistor Fabrication Techniques: Different Transistor Fabrication Techniques are namely Alloy Transistor Micro Alloy Transistor Microalloy Diffused Transistor Diffuse Mesa Transistor Epitaxial Mesa Transistors Diffused Planar Transistor Annular Transistor 1. Alloy Transistor: For manufacture of alloy Transistor Fabrication Techniques, single-crystal n-type wafers are scribed into many small sections, or dice, each … (Read More)

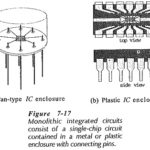

Transistor Fabrication Techniques: Different Transistor Fabrication Techniques are namely Alloy Transistor Micro Alloy Transistor Microalloy Diffused Transistor Diffuse Mesa Transistor Epitaxial Mesa Transistors Diffused Planar Transistor Annular Transistor 1. Alloy Transistor: For manufacture of alloy Transistor Fabrication Techniques, single-crystal n-type wafers are scribed into many small sections, or dice, each … (Read More)Integrated Circuits Fabrication Process: IC Types – An Integrated Circuits Fabrication Process consists of several interconnected transistors, resistors, etc., all contained in one small package with external connecting terminals. The circuit may be entirely self-contained, requiring only input and output connections … (Read More)

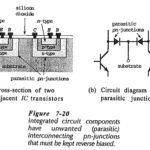

Integrated Circuit Components: The Integrated Circuit Components are namely, Transistors and Diodes: The epitaxial planar diffusion process described already is normally employed for the manufacture of IC transistors and diodes. Collector, base, and emitter regions are diffused into a silicon substrate and surface terminals … (Read More)