Types of Insulators in Transmission Lines:

The overhead line conductors should be supported on the poles or towers in such a way that currents from conductors do not flow to earth through supports i.e., line conductors must be properly insulated from supports. This is achieved by securing line conductors to supports with the help of insulators. The insulators provide necessary insulation between line conductors and supports and thus prevent any leakage current from conductors to earth. In general, Types of Insulators in Transmission Lines should have the following desirable properties of insulators:

- High mechanical strength in order to withstand conductor load, wind load etc.

- High electrical resistance of insulator material in order to avoid leakage currents to earth.

- High relative permittivity of insulator material in order that dielectric strength is high.

- The insulator material be non-porous, free from impurities and cracks otherwise the permittivity will be lowered.

- High ratio of puncture strength to flashover.

The most commonly used material for insulators of overhead line is porcelain but glass, steatite and special composition materials are also used to a limited extent. Porcelain is produced by firing at a high temperature a mixture of kaolin, feldspar and quartz. It is stronger mechanically than glass, gives less trouble from leakage and is less effected by changes of temperature.

Different Types of Insulators in Transmission Lines:

The successful operation of an overhead Groo line depends to a considerable extent upon cond the proper selection of insulators. There are several Types of Insulators in Transmission Lines but the most commonly used are pin type, suspension type, strain insulator and shackle insulator.

1. Pin Type Insulator:

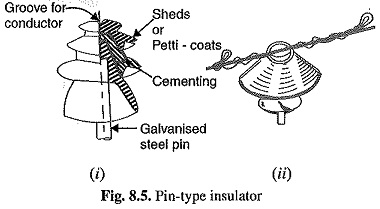

The part section of a pin type insulator is shown in Fig.8.5 (i). As the name suggests, the pin type insulator is secured to the cross-arm on the pole. There is a groove on the upper end of the insulator for housing the conductor. The conductor passes through this groove and is bound by the annealed wire of the same material as the conductor [See Fig. 8.5 (ii)].

Pin type insulators are used for transmission and distribution of electric power at voltages upto 33 kV. Beyond operating voltage of 33 kV, the pin type insulators become too bulky and hence uneconomical.

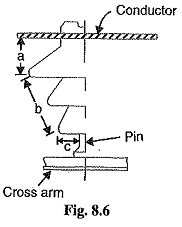

Causes of Insulator Failure: Insulators are required to withstand both mechanical and electrical stresses. The latter type is primarily due to line voltage and may cause the breakdown of the insulator. The electrical breakdown of the insulator can occur either by flash-over or puncture. In flash over, an arc occurs between the line conductor and insulator pin(i.e., earth) and the discharge jumps across the air gaps, following shortest distance. Fig. 8.6 shows the arcing distance (i.e. a + b + c) for the insulator. In case of flash-over, the insulator will continue to act in its proper capacity unless extreme heat produced by the arc destroys the Insulator.

In case of puncture, the discharge occurs from conductor to pin through the body of the insulator: When such breakdown is involved, the insulator is permanently destroyed due to excessive heat. In practice, sufficient thickness of porcelain is provided in the insulator to avoid puncture by the line voltage. The ratio of puncture strength to flash-over voltage is known as safety factor i.e.,

It is desirable that the value of safety factor is high so that flash-over takes place before the insulator gets punctured. For pin type insulators, the value of safety factor is about 10.

2. Suspension Type Insulator:

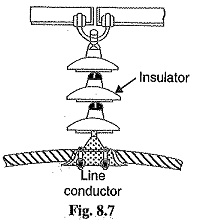

The cost of pin type insulator increases rapidly as the working voltage is increased. Therefore, In this Types of Insulators in Transmission Lines insulator is not economical beyond 33 kV. For high voltages (>33 kV), it is a usual practice to use suspension type insulators shown in Fig. 8.7. They consist of a number of porcelain discs connected in series by metal links in the form of a string. The conductor is suspended at the bottom end of this string while the other end of the string is secured to the cross arm of the tower. Each unit or disc is designed for low voltage, say 11 kV. The number of discs in series would obviously depend upon the working voltage. For instance, if the working voltage is 66 kV, then six discs in series will be provided on the string.

Advantages of Suspension Type Insulator:

- Suspension type insulators are cheaper than pin type insulators for voltages beyond 33 kV.

- Each unit or disc of suspension type insulator is designed for low voltage,usually, 11kV Depending upon the working voltage, the desired number of discs can be connected in series.

- If any one disc is damaged, the whole string does not become useless because the damaged disc can be replaced by the sound one,

- The suspension arrangement provides greater flexibility to the line. The connection at the cross arm is such that insulator string is free to swing in any direction and can take up the position where mechanical stresses me minimum.

- In case of increased demand on the transmission line, it is found more satisfactory to supply the greater demand by raising the line voltage than to provide another set of conductors. The additional insulation required for the raised voltage can be easily obtained in the suspension arrangement by adding the desired number of discs.

- The suspension type insulators are generally used with steel towers. As the conductors run below the earthed cross-mm of the tower, therefore, this arrangement provides partial protection from lightning.

3. Strain insulators:

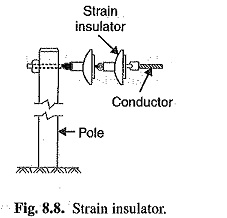

When there is a dead end of the line or there is corner or sharp curve, the line is subjected to greater tension. In order to relieve the line of excessive tension, strain insulators me used For low voltage lines (< 11 kV), shackle insulators are used as strain insulators. However, for high voltage transmission lines, strain insulator consists of an assembly of suspension insulators as shown in Fig. 8.8. The discs of strain insulators are used in the vertical plane. When the tension in lines is exceedingly high, as at long river spans, two or more strings are used in parallel.

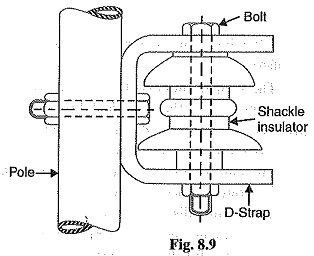

4. Shackle insulators:

In early days, the shackle insulators were used as strain insulators. But now a days, they are used for low voltage distribution lines. Such insulators can be used either in a horizontal position or in a vertical position. They can be directly fixed to the pole with a bolt or to the cross arm. Fig. 8.9 shows a shackle insulator fixed to the pole. The conductor in the groove is fixed with a soft binding wire.