Cycloconverter Control of Induction Motor:

Cycloconverter Control of Induction Motor allows variable frequency and variable voltage supply to be obtained from a fixed voltage and frequency ac supply.

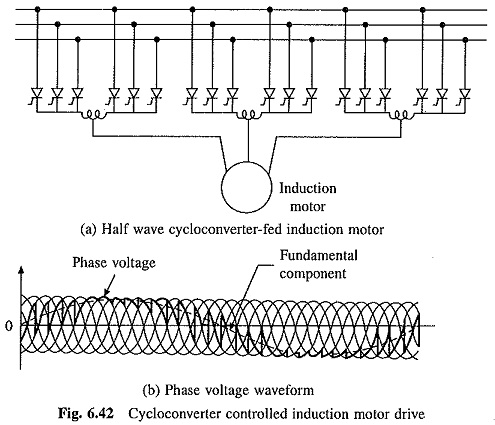

A half-wave Cycloconverter Control of Induction Motor is shown in Fig. 6.42 along with the nature of its output voltage waveform. Because of low harmonic content when operating at low frequencies, smooth motion is obtained at low speeds.

Harmonic content increases with frequency, making it necessary to limit the maximum output frequency to 40% of the source frequency. Thus, maximum speed is restricted to 40% of synchronous speed at the mains frequency.

A motor with large leakage inductance is used in order to minimize derating and torque pulsations due to harmonics in motor current.

The drives has regenerative braking capability. Full four-quadrant operation is obtained by reversing the phase sequence of motor terminal voltage. Since cycloconverter employs large number of thyristors, it becomes economically acceptable only in large power drives.

Cycloconverter Control of Induction Motor drive has applications in high power drives requiring good dynamic response but only low speed operation e.g. in ball mill in a cement plant.

The low speed operation is obtained by feeding a motor with large pole numbers from a Cycloconverter Control of Induction Motor operating at low frequencies. These drives are called gearless drives because, unlike conventional drives, the low speed operation of load is obtained without a reduction gear, thus eliminating the associated cost, space and maintenance.